Making The Most Of Machinery Long Life: Buying Costs Undercarriage Parts Solutions

Making The Most Of Machinery Long Life: Buying Costs Undercarriage Parts Solutions

Blog Article

Necessary Guide to Undercarriage Components for Heavy Tools

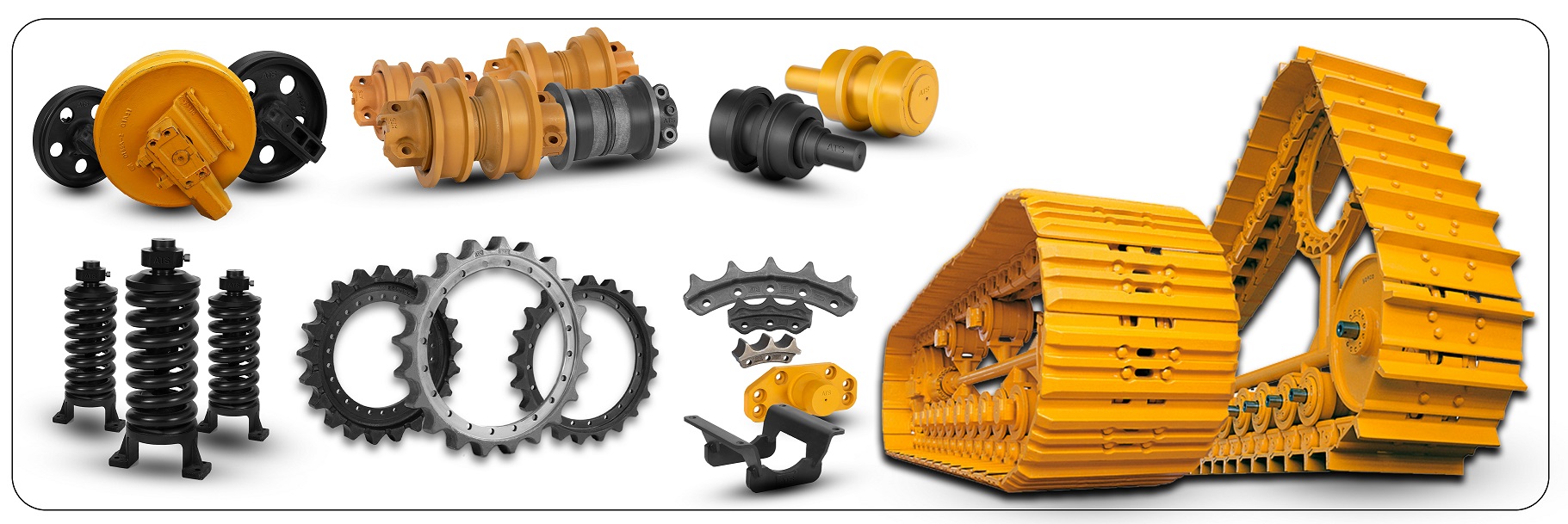

When it comes to heavy equipment, the undercarriage plays an important duty in making certain effective and smooth procedures. From track chains to idlers and rollers, each component contributes to the general performance of the equipment.

Significance of Undercarriage Components

Comprehending the crucial function that undercarriage components play in the performance and durability of hefty tools is extremely important for effective upkeep and procedure - undercarriage parts. The undercarriage parts create the foundation on which the whole equipment runs, sustaining the weight of the devices, offering security, and taking in shock loads during operation. A properly maintained undercarriage not just ensures smooth operation however likewise contributes dramatically to lowering downtime and repair service prices

The undercarriage is composed of different important parts such as track chains, track footwear, gears, idlers, rollers, and track frameworks. Each of these elements plays an essential function in the general functionality of the devices. For instance, the track chains and track footwear aid in offering traction and assistance, while the idlers and gears aid in driving the tracks smoothly. Regular evaluation, timely upkeep, and substitute of worn-out undercarriage parts are essential to stop breakdowns and take full advantage of the life expectancy of the hefty tools. Fundamentally, purchasing high-grade undercarriage components and guaranteeing their correct care is vital for ideal performance and toughness of heavy equipment.

Sorts Of Track Chains

Track chains are necessary components of heavy equipment undercarriages, supplying the required traction and assistance for efficient operation. There are largely two kinds of track chains utilized in hefty devices: secured and lubricated track chains (SALT) and dry track chains. Secured and lubed track chains are frequently discovered in modern heavy machinery. These chains are pre-lubricated and sealed to avoid dirt, particles, and wetness from entering the chain joints, making sure smooth procedure and prolonging the chain's life-span. On the other hand, dry track chains need routine manual lubrication to maintain optimal efficiency and stop early wear.

Role of Rollers and Idlers

Rollers and idlers play an essential function in supporting and leading the track chains of hefty tools undercarriages, adding to the overall stability and effectiveness of the equipment. Rollers are made to sustain the weight of the devices and provide a smooth surface for the track chain to relocate along. They assist distribute the weight evenly, reducing extreme wear on the track chain and making certain correct traction. Idlers, on the various other hand, overview the track chain and assistance keep proper stress throughout the undercarriage system. By leading the track chain in a controlled way, idlers stop too much side-to-side motion, minimizing the threat of derailment and irregular wear.

Together, idlers and rollers operate in consistency to guarantee that the track chain remains in location, visit our website also on harsh terrain, enhancing the devices's performance and long life. Proper upkeep and normal assessment of rollers and idlers are necessary to avoid premature wear and potential break downs, eventually taking full advantage of the effectiveness and life-span of hefty devices undercarriages.

Understanding Sprockets

One critical aspect of gears is ensuring appropriate alignment and tension to avoid early wear and damages. Misaligned gears can trigger uneven wear on the track chain, resulting in lowered efficiency and potential safety and security threats. Normal maintenance and examination of sprockets are important to identify any type of indications of wear or misalignment promptly.

In moved here addition, sprockets are available in various dimensions and tooth configurations, depending on the particular hefty devices and its intended usage. Correct selection of sprockets based on the equipment's requirements is important to guarantee optimal efficiency and durability of the undercarriage system. Understanding the duty of gears and their maintenance demands is vital for taking full advantage of the efficiency and lifespan of hefty devices undercarriages.

Maintenance Tips for Durability

To ensure the prolonged resilience and optimal capability of heavy devices undercarriages, thorough maintenance practices are important. Routinely evaluating undercarriage parts such as track shoes, rollers, idlers, and gears for damage is crucial. Replace any type of worn or broken elements promptly to protect against further damage to the undercarriage system. Proper track stress adjustment is likewise important for lowering early wear on undercarriage parts. Over-tensioning can lead to enhanced stress on the elements, while under-tensioning can create track slippage and accelerated wear. In addition, maintaining the undercarriage clean from debris buildup, mud, and various other pollutants can aid protect against corrosion and prolong the life-span of the parts. Greasing the undercarriage components at advised intervals will additionally reduce friction and wear. Last but not least, organizing regular maintenance talk to trained professionals can determine potential problems beforehand and address them before they intensify, inevitably making best use of the longevity of hefty devices undercarriages.

Final Thought

In final thought, undercarriage parts are important components for hefty devices, playing critical duties in preserving security and functionality. Comprehending the different sorts of track chains, idlers, gears, and rollers is necessary for correct upkeep and longevity of the equipment. By following maintenance ideas and routinely inspecting and changing used parts, operators can make certain the optimal performance and efficiency of their heavy machinery. Proper care and interest to undercarriage parts are essential to optimizing tools life-span and performance.

The undercarriage is composed of numerous vital parts such as track chains, track footwear, gears, idlers, rollers, and track structures. The track chains and track footwear aid in offering traction and support, while the gears and idlers link help in driving the tracks smoothly (undercarriage parts). There are mostly 2 kinds of track chains utilized in hefty equipment: sealed and lubed track chains (SALT) and completely dry track chains. Appropriate option and maintenance of track chains are essential to guarantee the overall efficiency and durability of heavy equipment undercarriages

Sprockets are integral parts of heavy devices undercarriages, responsible for moving power from the equipment to the track chain.

Report this page